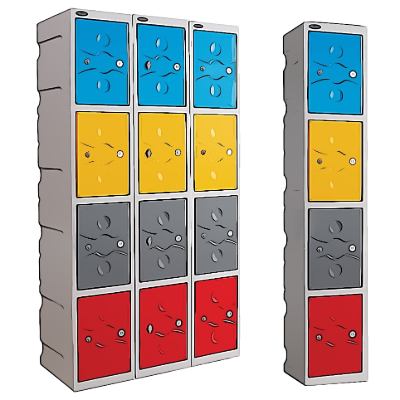

Plastic Lockers

Plastic Storage Locker Solutions

Our plastic lockers are designed for secure personal storage and come in various sizes and colours to suit diverse workplace requirements. These units provide durable, compartmentalised storage with clear labelling options, making them ideal for managing staff's belongings efficiently. Suitable for indoor or outdoor use, plastic lockers help businesses meet regulatory requirements while offering a practical and hygienic solution for everyday operations.

Hygienic Food Lockers for Demanding Environments

Plastic lockers are increasingly adopted across food processing, education, hospitality, and leisure sectors due to their resistance to corrosion and ease of cleaning. These food lockers are suitable for both wet and dry areas, offering a non-porous surface that can be hosed down without risk of rust. Their robust construction ensures long-term use while supporting hygiene standards in regulated environments.

Plastic Locker - Junior - Solid Door - HACCP Compliant - Flat Top - 3 Tier - Blue - JUNLOCKERBLUE

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments

- Free – standing

- Colour: Blue

- Flat roof

- Fully UV resistant and fully recyclable

- Fitted with a lockable camlock

- Dimensions: 1260 (H) x 400 (W) x 425 (D) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Junior - Solid Door - HACCP Compliant - Flat Top - 3 Tier - Coloured - JUNLOCKERCOL

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments

- Free – standing

- Colour: Yellow, red and green

- Flat roof

- Fully UV resistant and fully recyclable

- Fitted with a lockable camlock

- Dimensions: 1260 (H) x 400 (W) x 425 (D) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Flat Top - 2 Tier - LOCKER2SOLID-FLAT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 2 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Flat Top - 3 Tier - LOCKER3SOLID-FLAT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Flat Top - 4 Tier - LOCKER4SOLID-FLAT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 4 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Flat Top - 6 Tier - LOCKER6SOLID-FLAT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 6 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Slanted Top - 2 Tier - LOCKER2SOLID-SLANT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 2 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Slanted Top - 3 Tier - LOCKER3SOLID-SLANT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Slanted Top - 4 Tier - LOCKER4SOLID-SLANT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 4 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Solid Door - HACCP Compliant - Slanted Top - 6 Tier - LOCKER6SOLID-SLANT

- The HACCP compliant solid plastic locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 6 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Flat Top - 2 Tier - LOCKER2MESH-FLAT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 2 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Flat Top - 3 Tier - LOCKER3MESH-FLAT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Flat Top - 4 Tier - LOCKER4MESH-FLAT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 4 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Flat roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1830 (H) x 310 (W) x 380 (D) mm - (1870 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Slanted Top - 2 Tier - LOCKER2MESH-SLANT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 2 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Slanted Top - 3 Tier - LOCKER3MESH-SLANT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 3 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Locker - Mesh Door - HACCP Compliant - Slanted Top - 4 Tier - LOCKER4MESH-SLANT

- The HACCP compliant plastic mesh locker is maintenance free, robust and ultra hygienic

- Full locker unit consisting of 4 locker compartments and galvanised hinge rods

- Free – standing with adjustable feet

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Optional galvanised frames available

- Dimensions: 1940 (H) x 310 (W) x 380 (D) mm - (1980 (H) mm with adjustable feet)

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Shelf for Plastic Locker - Adjustable - LOCKERSHELF

- Additional shelf for plastic locker

- Colour: Black

- Fully UV resistant and fully recyclable

- Approved by the FDA for use in food processing and high hygiene environments, resistant to acid, alkali and corrosion

- Only suitable for 2, 3 and 4 tier solid and mesh plastic lockers

- Fits on ridges inside locker and is adjustable

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Wall Mounted Kit for Plastic Locker - WALLMOUNTKIT

- Aluminium wall mounting bracket used to fix solid plastic locker(s) to a brick wall

- 8mm sleeve anchor and pop rivets supplied

- Material: Aluminium

- Size: 50mm (H) x 310 (W) x 25 (D) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Locker - HACCP Compliant - Flat Top - LOCKERFOOD-FLAT

- The HACCP compliant solid plastic food locker is maintenance free, robust, ultra hygienic

- Flat roof and the door has louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 300 (H) x 310 (W) x 380 (D) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Lockers on Frame - 2 x 5-Tier (10 Tiers) - Flat Top - HACCP - 10FF-FLAT

- The HACCP compliant solid plastic food locker is maintenance free, robust and ultra hygienic

- Includes a hot dipped galvanised frame which accommodates 10 food lockers (2 x lockers wide and 5 x lockers high)

- Flat roof and the door has louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 620 (L) x 380 (W) x 1600 (H) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Lockers on Frame - 3 x 5-Tier (15 Tiers) - Flat Top - HACCP - 15FF-FLAT

- The HACCP compliant solid plastic food locker is maintenance free, robust and ultra hygienic

- Includes a hot dipped galvanised frame which accommodates 15 food lockers (3 x lockers wide and 5 x lockers high)

- Flat roof and the door has louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 930 (L) x 380 (W) x 1600 (H) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Lockers on Frame - 4 x 5-Tier (20 Tiers) - Flat Top - HACCP - 20FF-FLAT

- The HACCP compliant solid plastic food locker is maintenance free, robust, and ultra hygienic

- Includes a hot dipped galvanised frame which accommodates 20 food lockers (4 x lockers wide and 5 x lockers high)

- Flat roof and the door has louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 1240 (L) x 380 (W) x 1600 (H) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Lockers on Frame - 5 x 5-Tier (25 Tiers) - Flat Top - HACCP - 25FF-FLAT

- The HACCP compliant solid plastic food locker is maintenance free, robust and ultra hygienic

- Includes a hot dipped galvanised frame which accommodates 25 food lockers (5 x lockers wide and 5 x lockers high)

- Flat roof and the door has louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 1550 (L) x 380 (W) x 1600 (H) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's

Plastic Food Locker - HACCP Compliant - Slanted Top - LOCKERFOOD-SLANT

- The HACCP compliant solid plastic food locker is maintenance free, robust, ultra hygienic

- Slanted roof and doors have louvres for ventilation

- Fully UV resistant and fully recyclable

- Blank 304 Stainless Steel ID plates

- Includes 304 Stainless Steel padlock eye

- Dimensions: 430 (H) x 310 (W) x 380 (D) mm

- Item delivery usually within 6 weeks

- Return Restrictions applicable - see Shipping and Returns T&C's